Applications for Rotech Motion Sensors/Encoders

The principle application for “Rotech” Heavy Duty Motion Sensors is as a Speed or Slow Down Switch on plant and machinery.

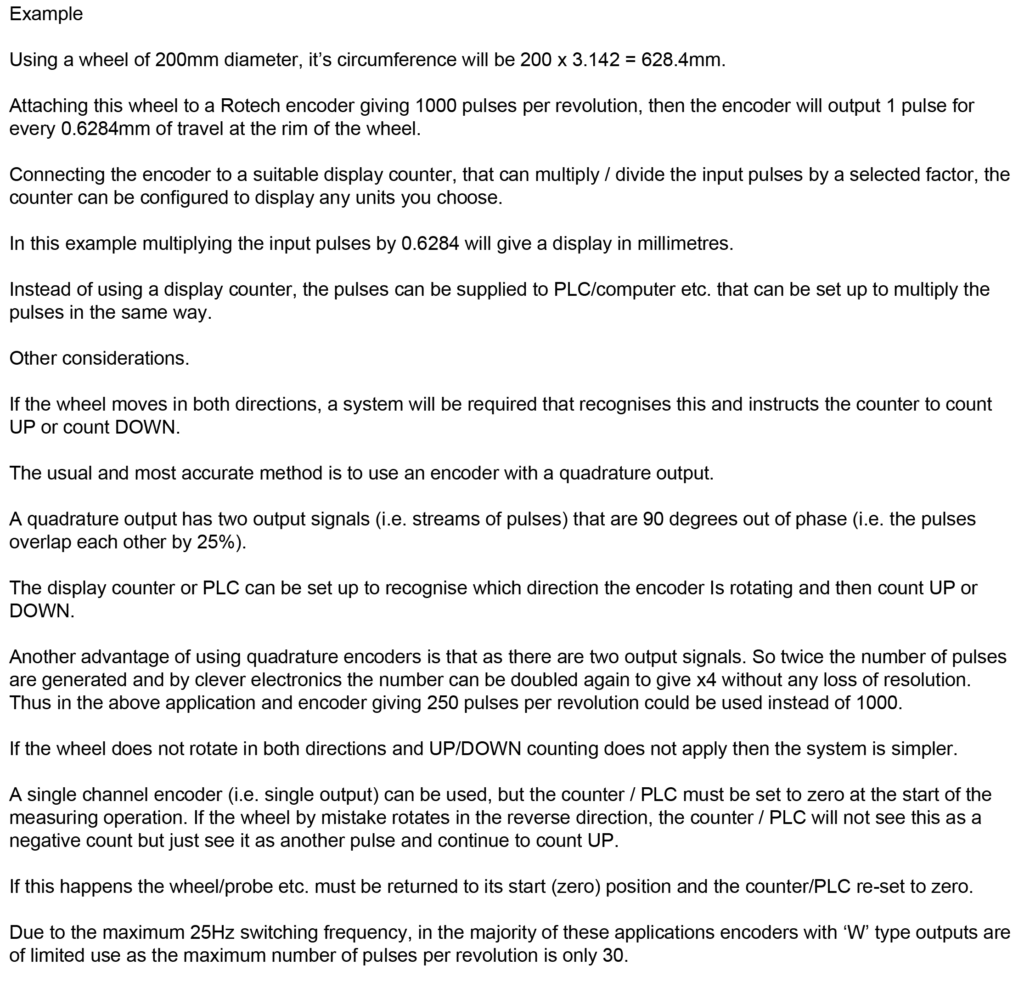

They can be fitted to Conveyor Belts, Elevators, Conveyor Screws, Crushers, Mixers, Valves and any other plant that presents a hazard if it stops or slows beneath its normal running speed.

They should always be installed at the end of the drive system.

On a Conveyor and Elevator they should be installed on the Tail Drum, Tail Roller, Snub Roller, Gravity Take up Roller or any roller that is driven by the conveyor belt itself. Alternatively the ‘Rotech’ Wheel Driven Motion Sensors can be fitted directly to run on the return side of the Conveyor Belt.

Any slowing down of the Drive Motor, Gearbox, Drive Chains, Drive Belts, or the conveyor belt slipping, etc, will result in the conveyor belt and the selected drum/roller slowing down which will be detected by the Motion Sensor.

All elements of the conveyor are therefore monitored.

The Heavy Duty Shaft Sensor should, unless special circumstances apply, never be fitted to the Drive Roller or Drum.

On Conveyor Screws the Heavy Duty Shaft Sensor should be installed to the non-driven end of the screw.

Shaft Sensors can give information on the speed, angular position, direction and number of revolutions completed by a rotating shaft.

Via racks, screws, slides, etc., all of these functions can be translated into linear functions.

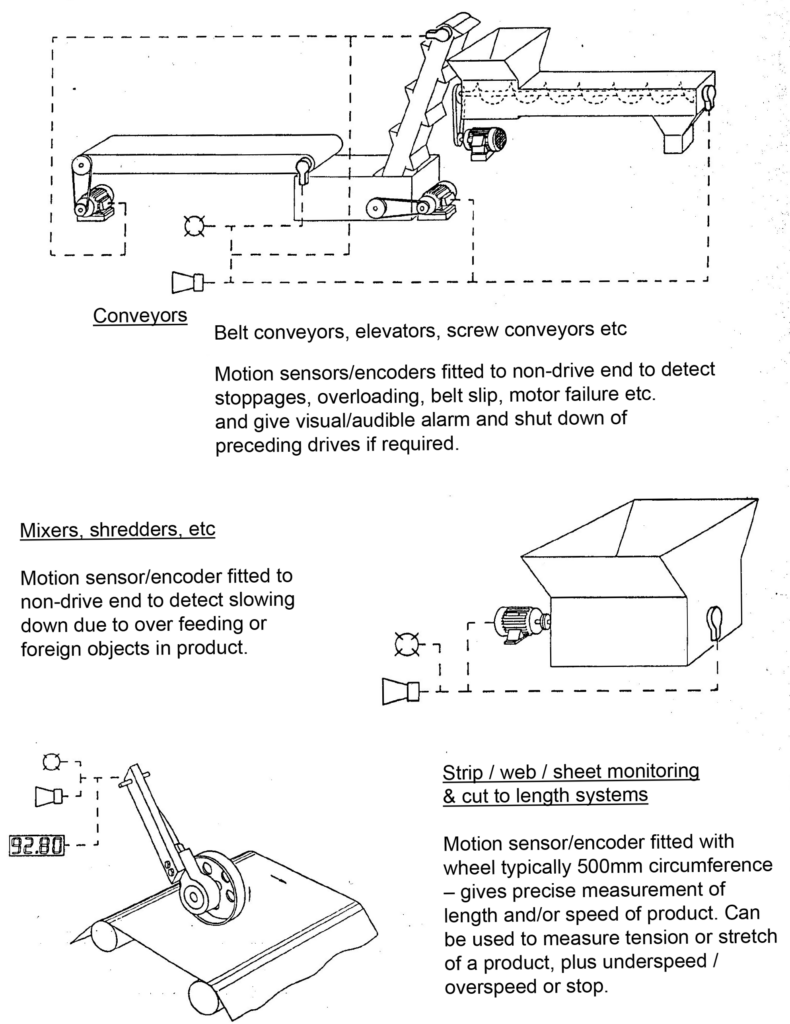

Although its use as a Speed Switch is the principle application of “Rotech” Motion Sensors/Encoders, they also fulfill a wide range of other applications in many types of industries.

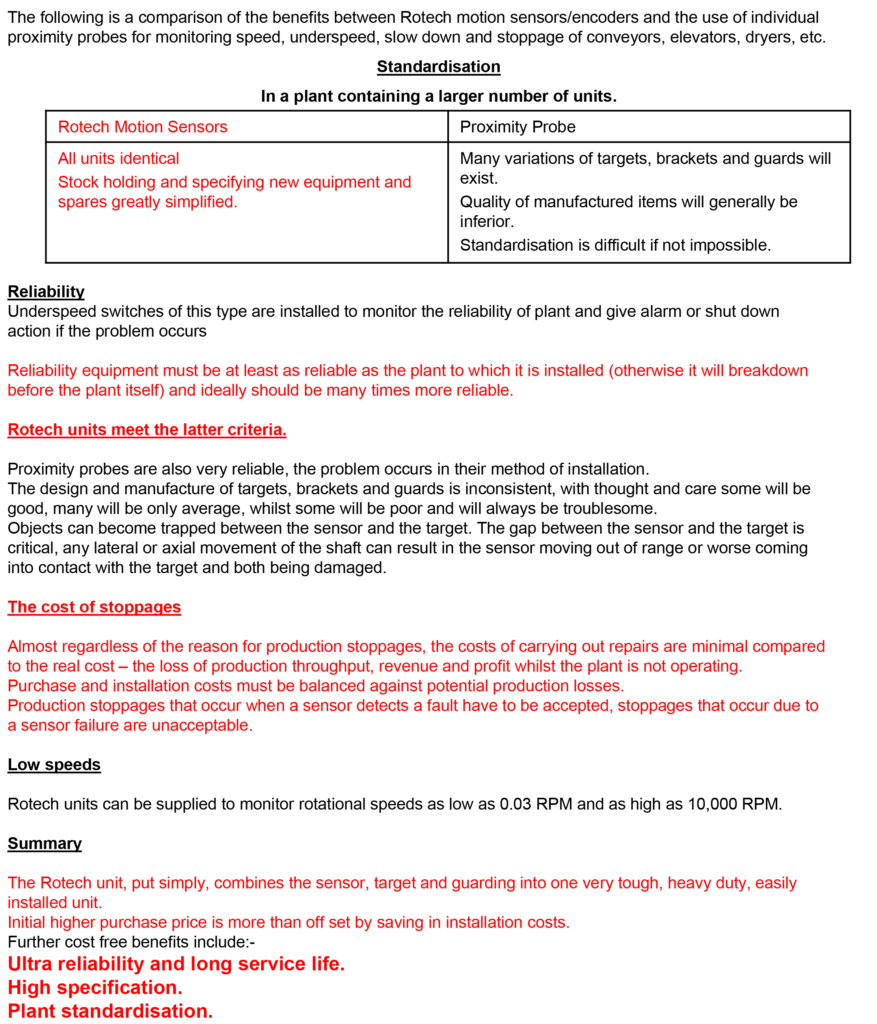

Cost Comparison

Product Technical Information

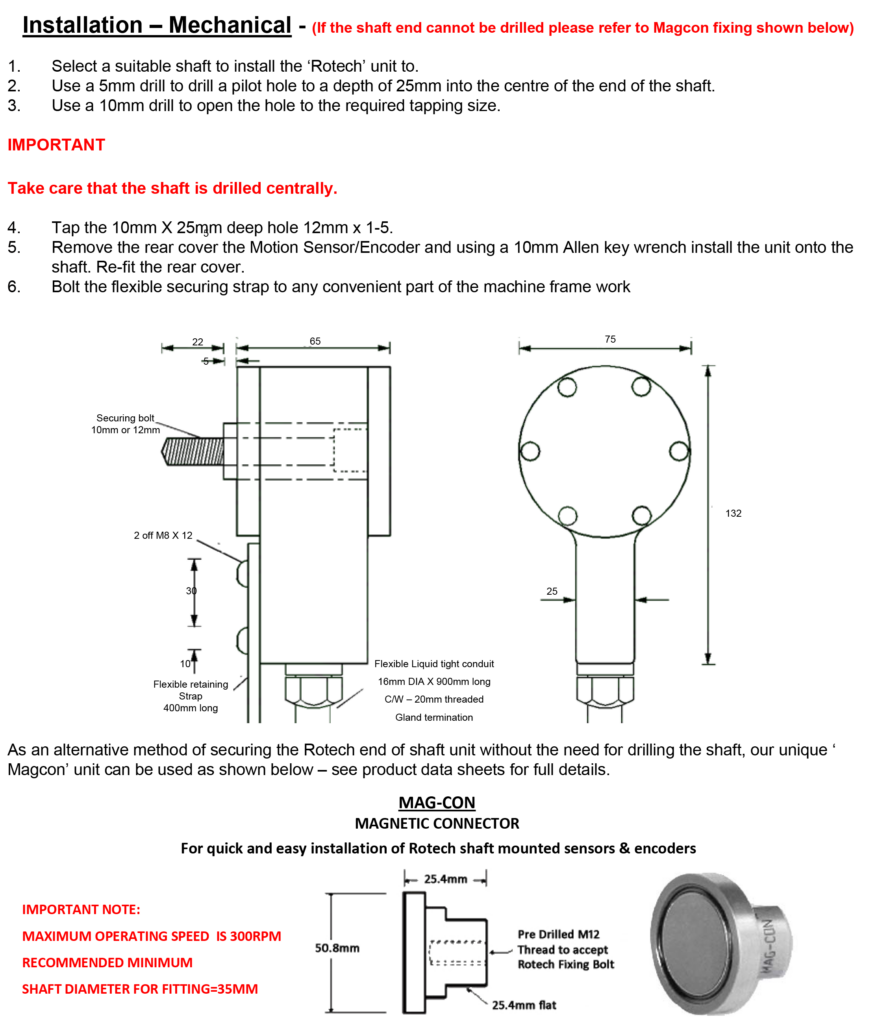

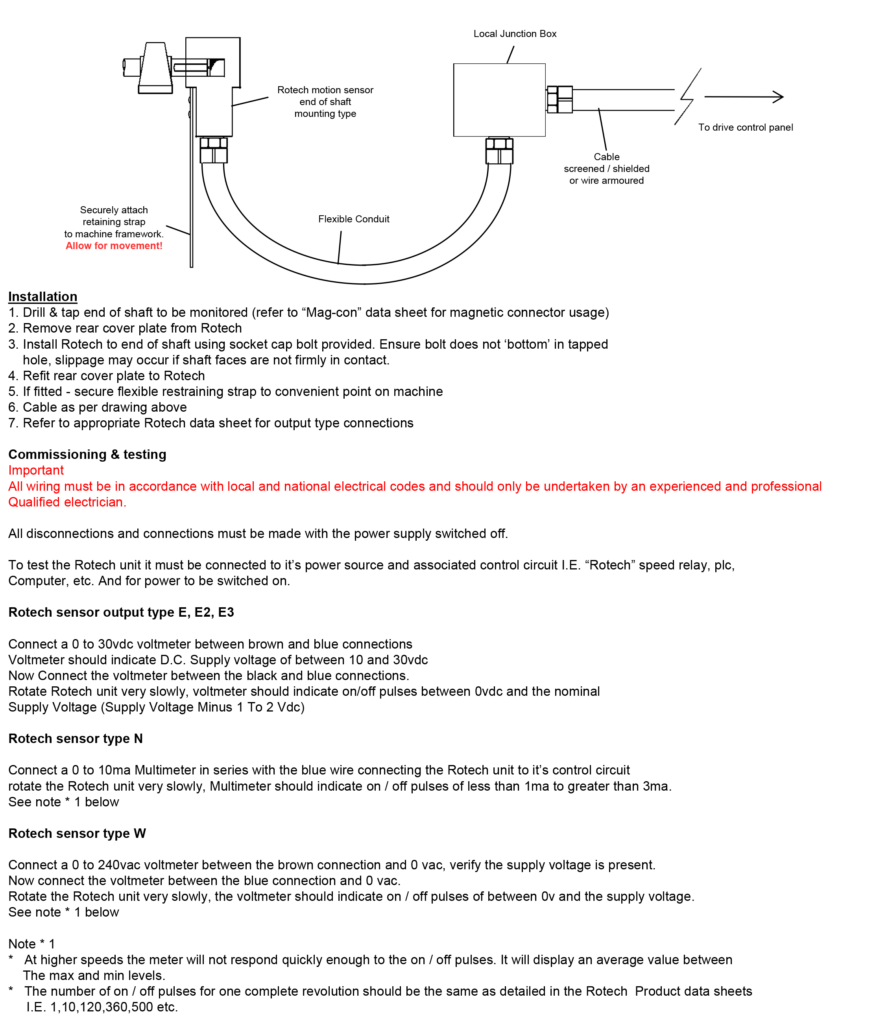

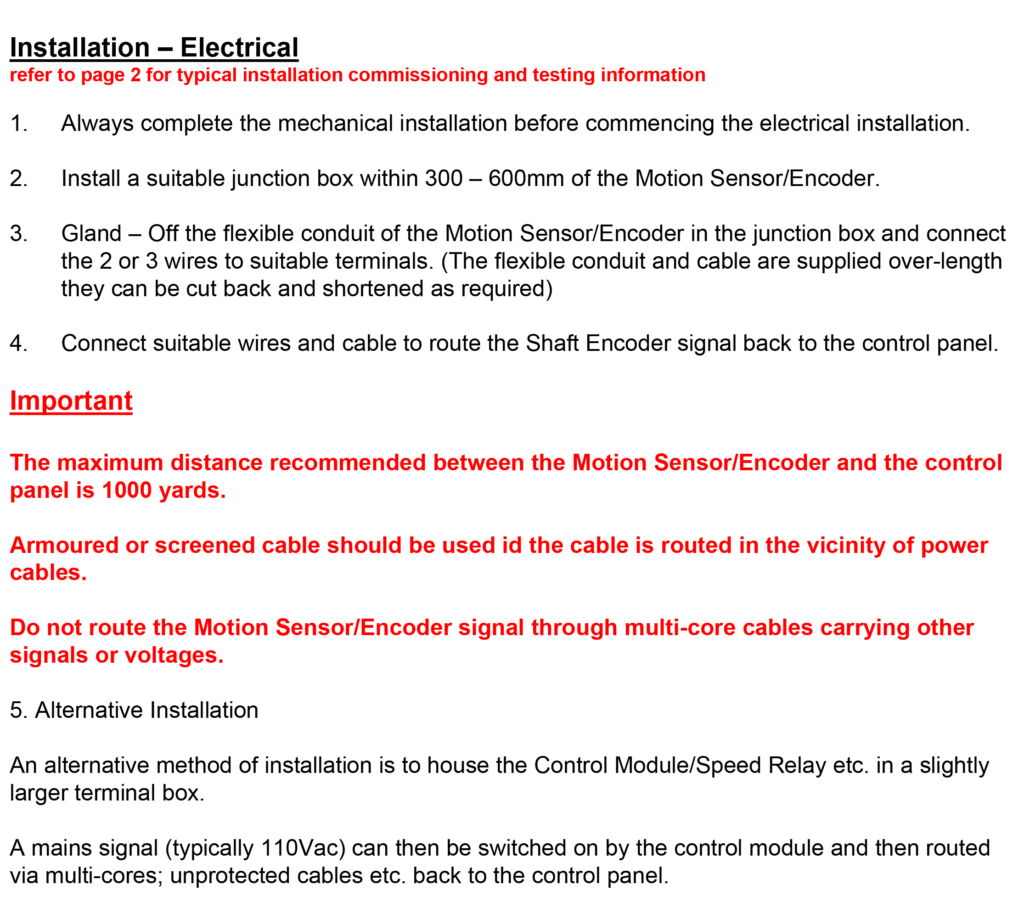

Installation End of Shaft

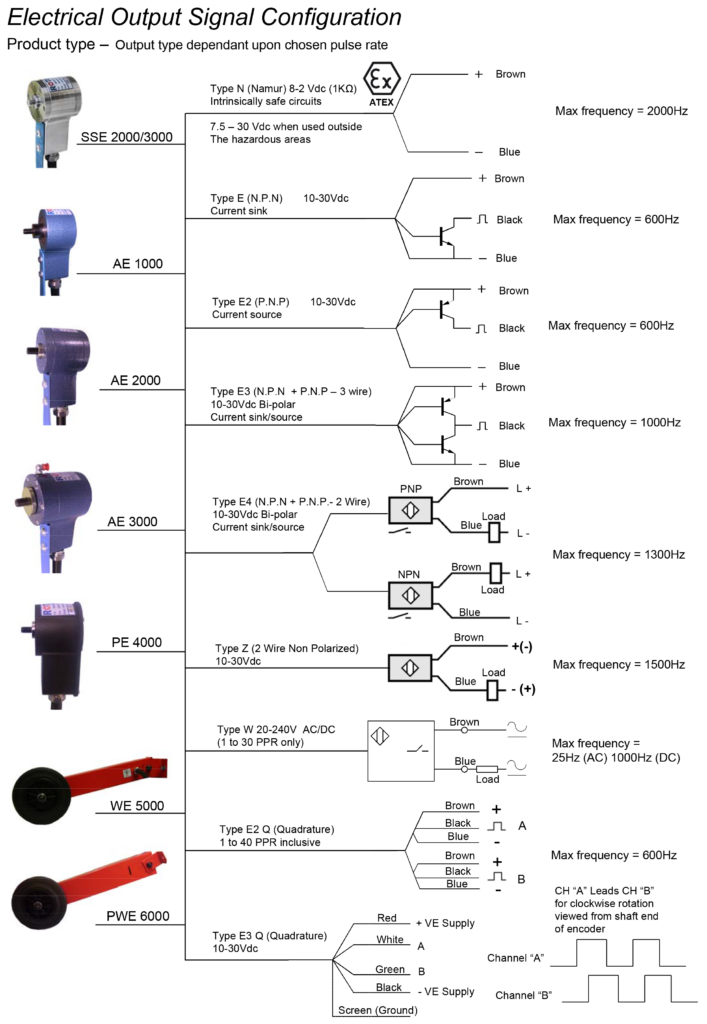

Output Signals Configuration

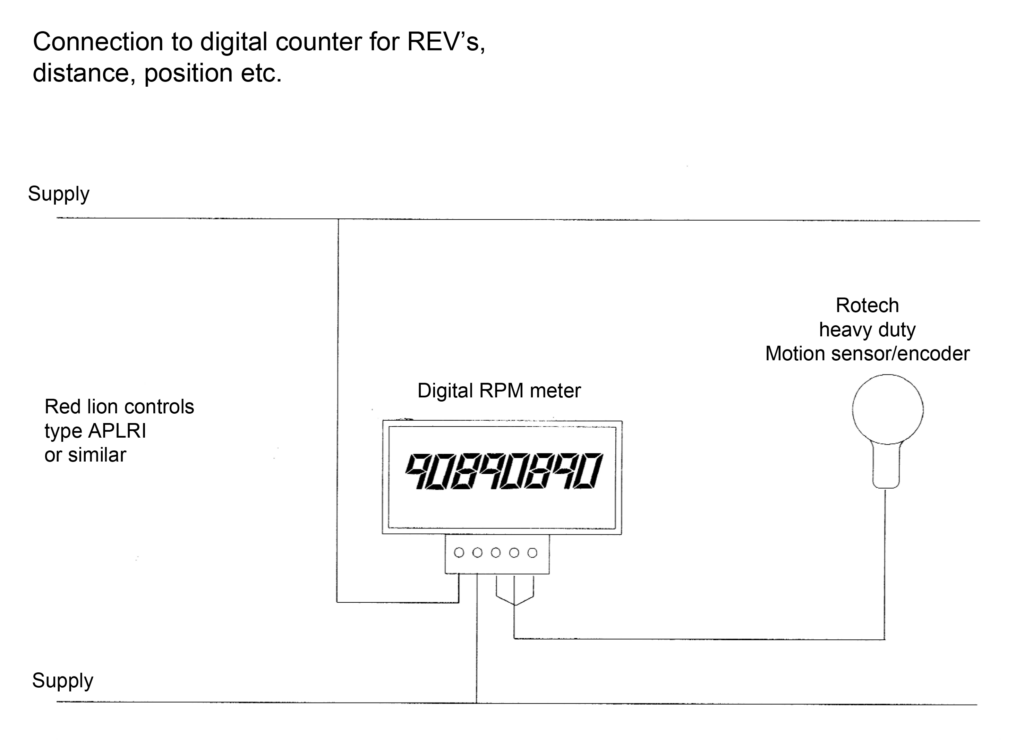

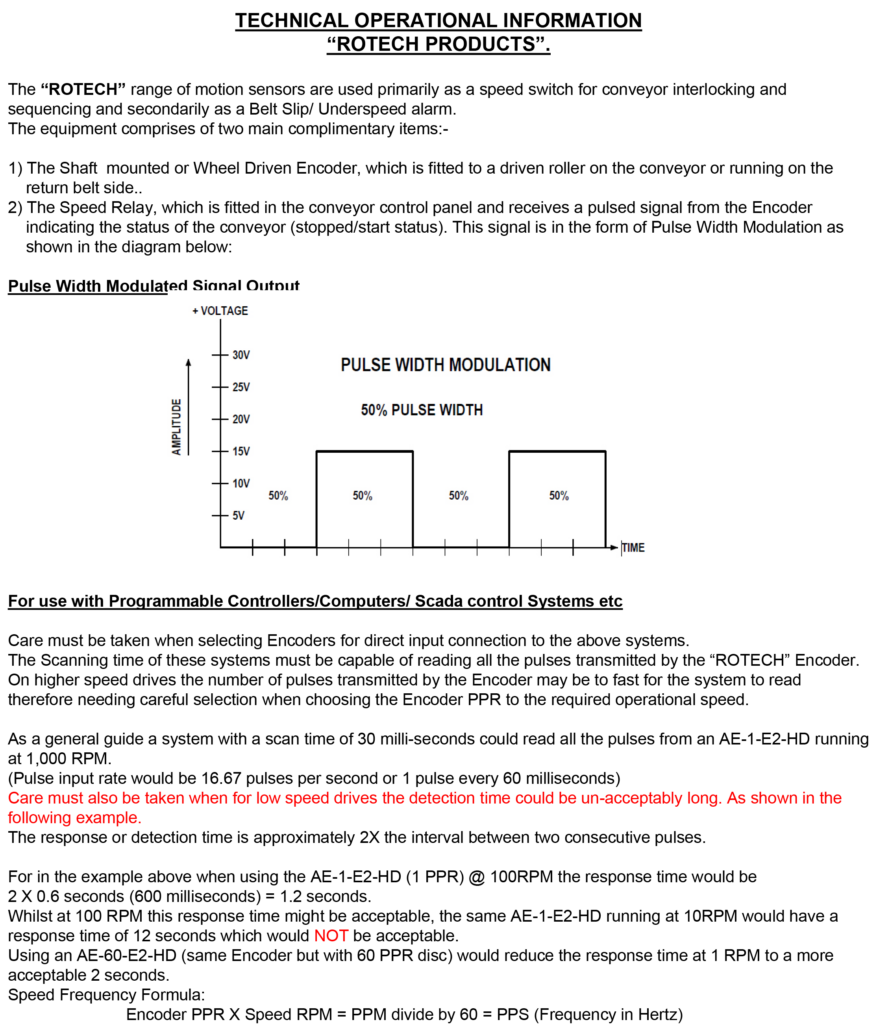

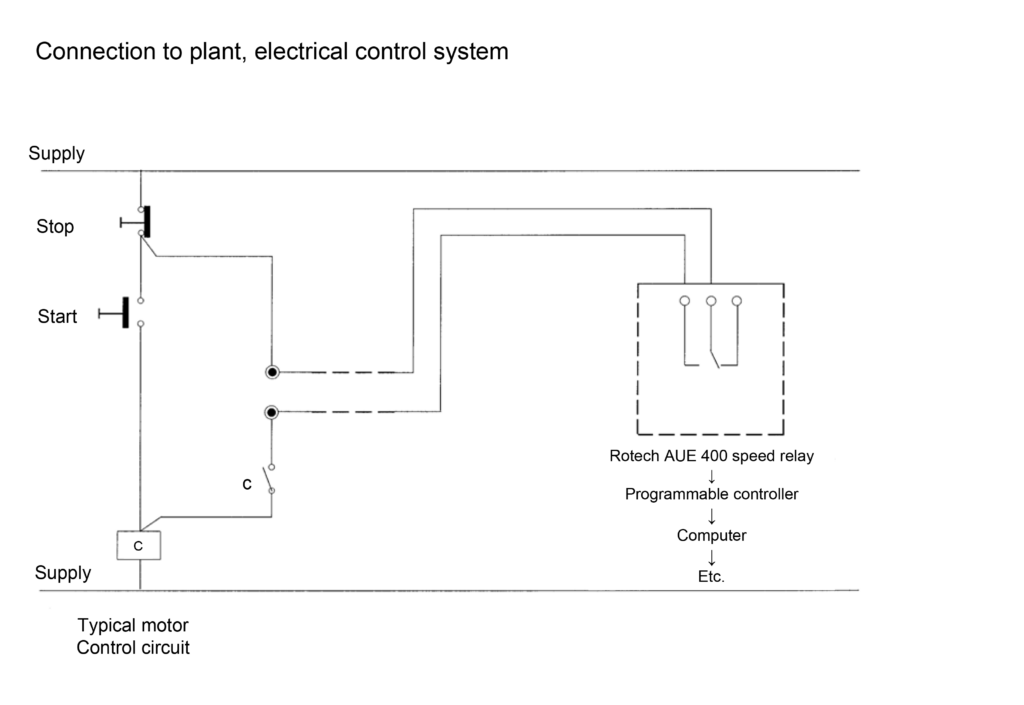

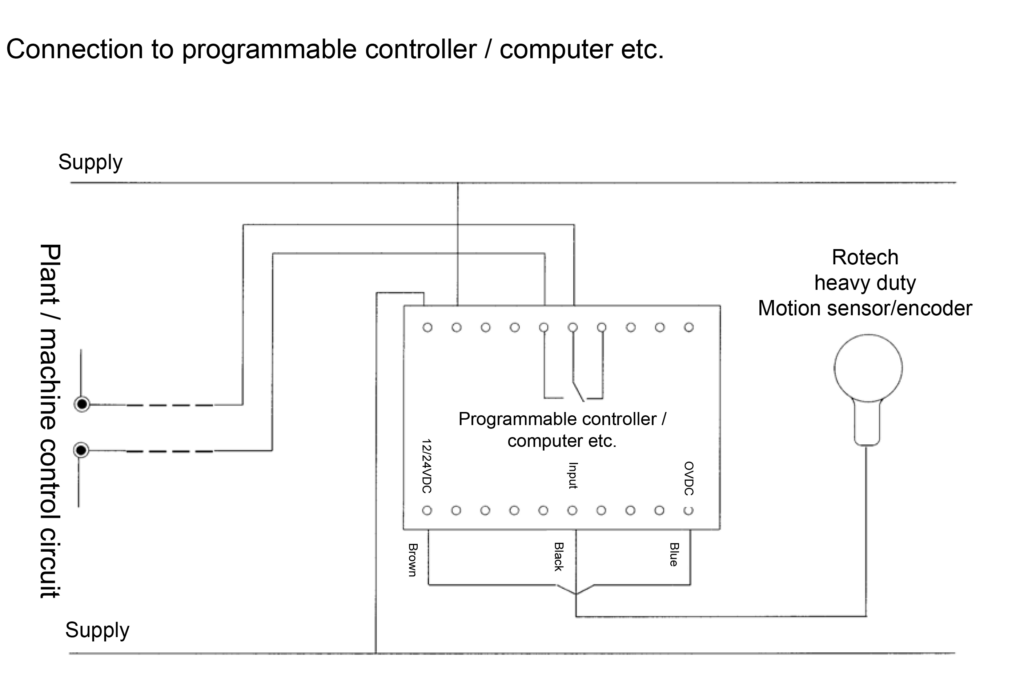

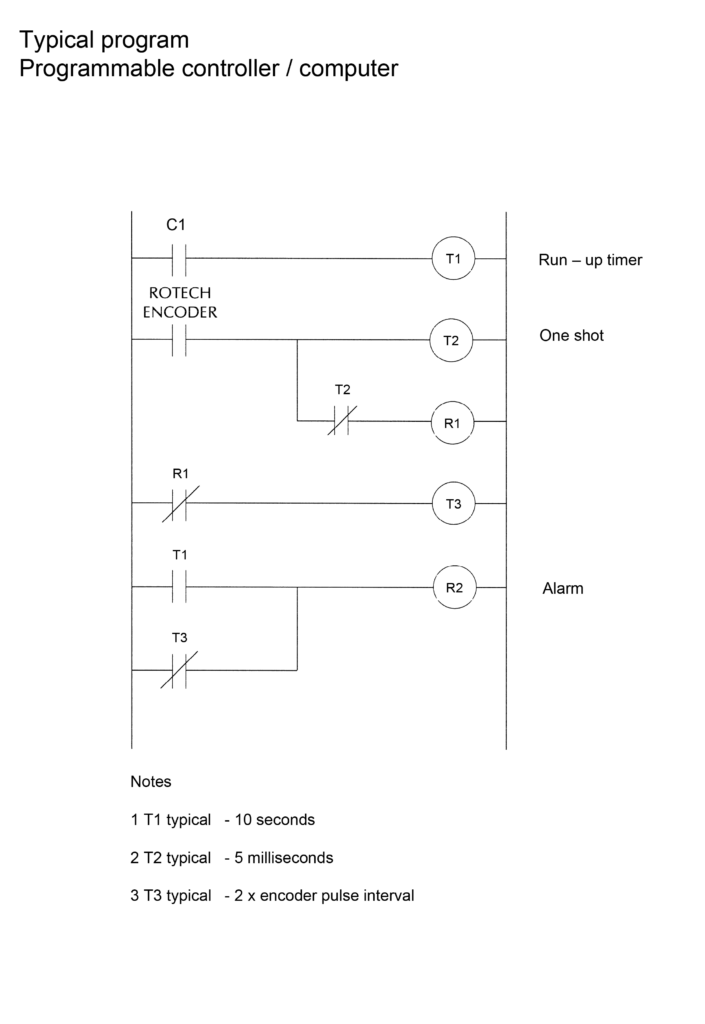

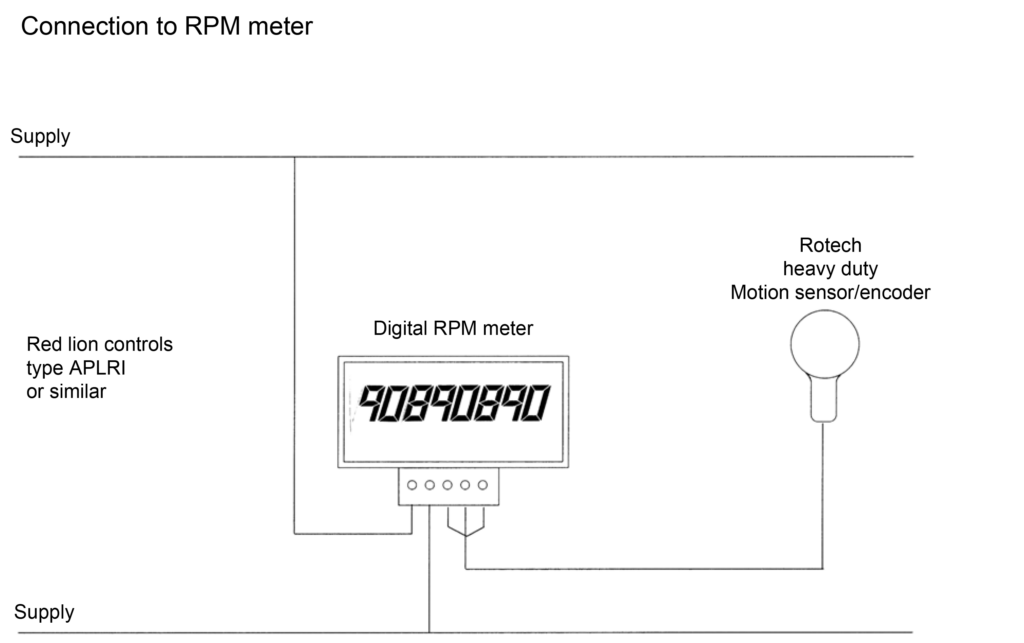

Plant/PLC Connection

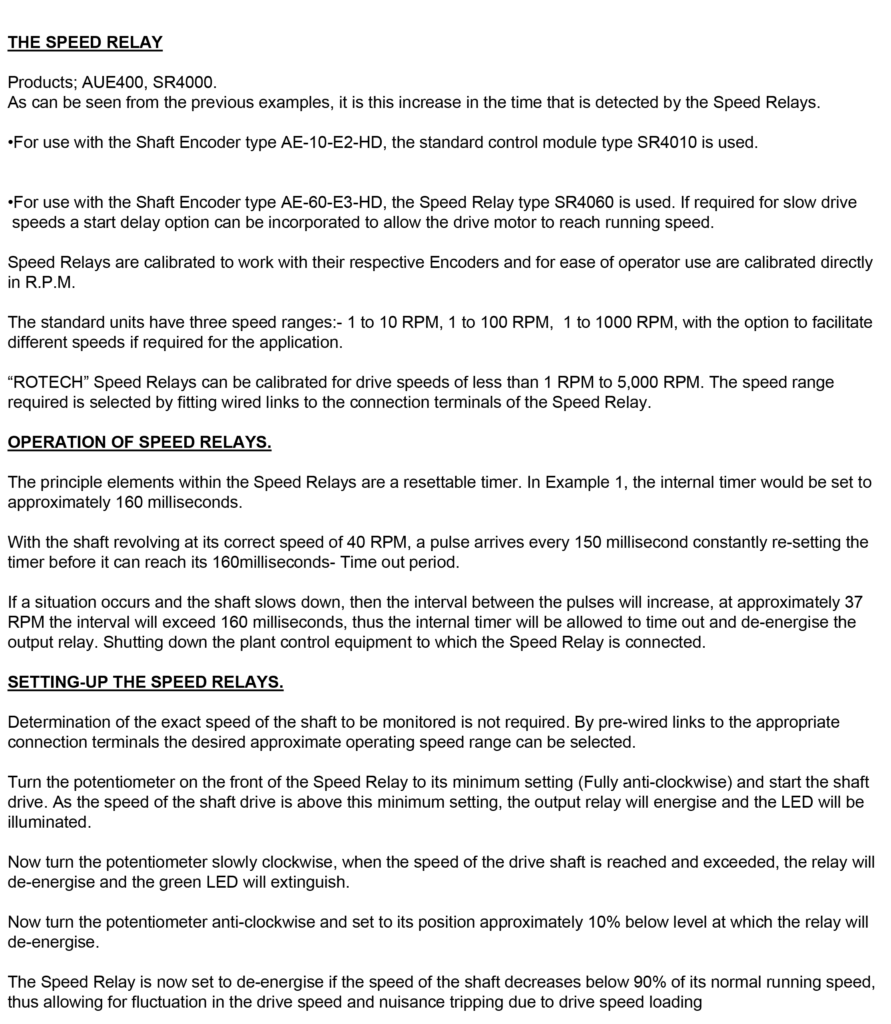

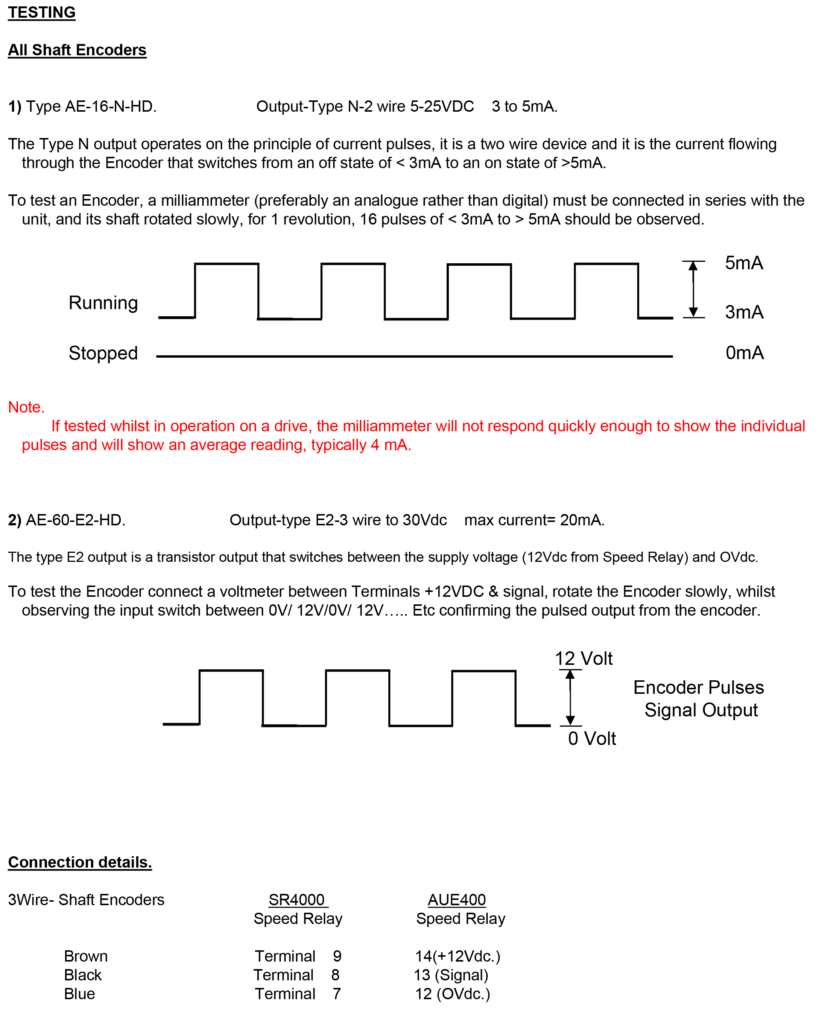

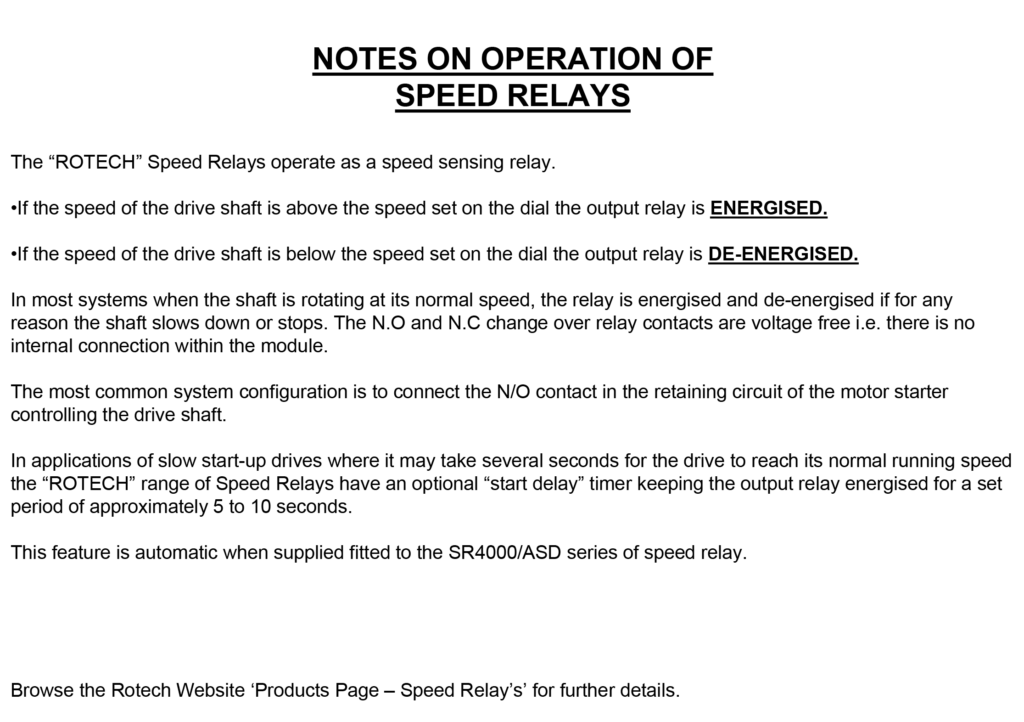

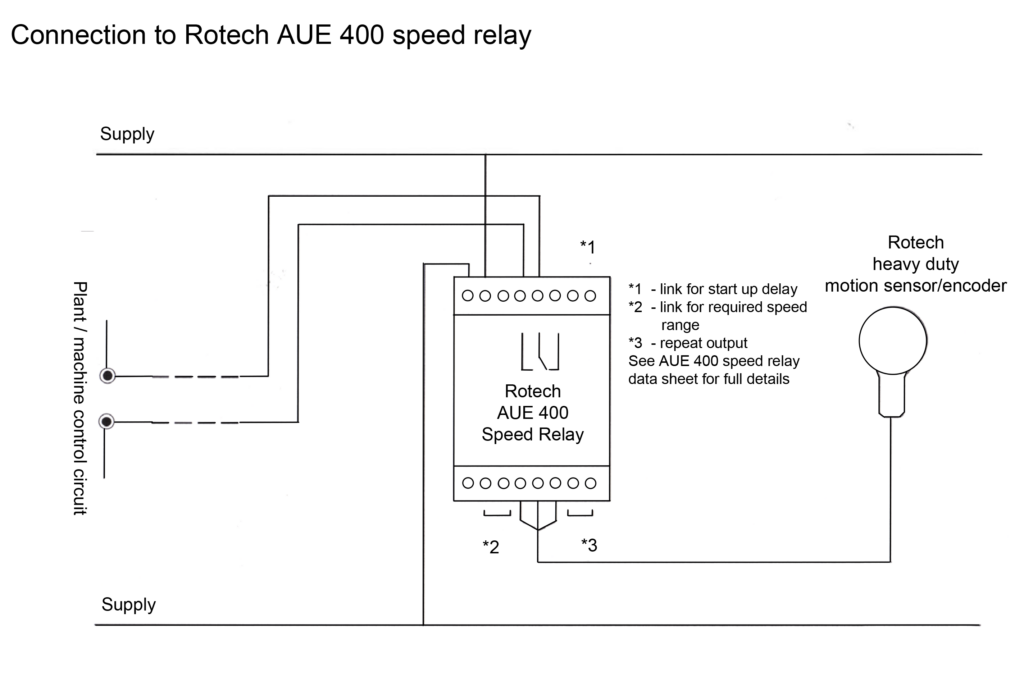

Speed Relay Connection

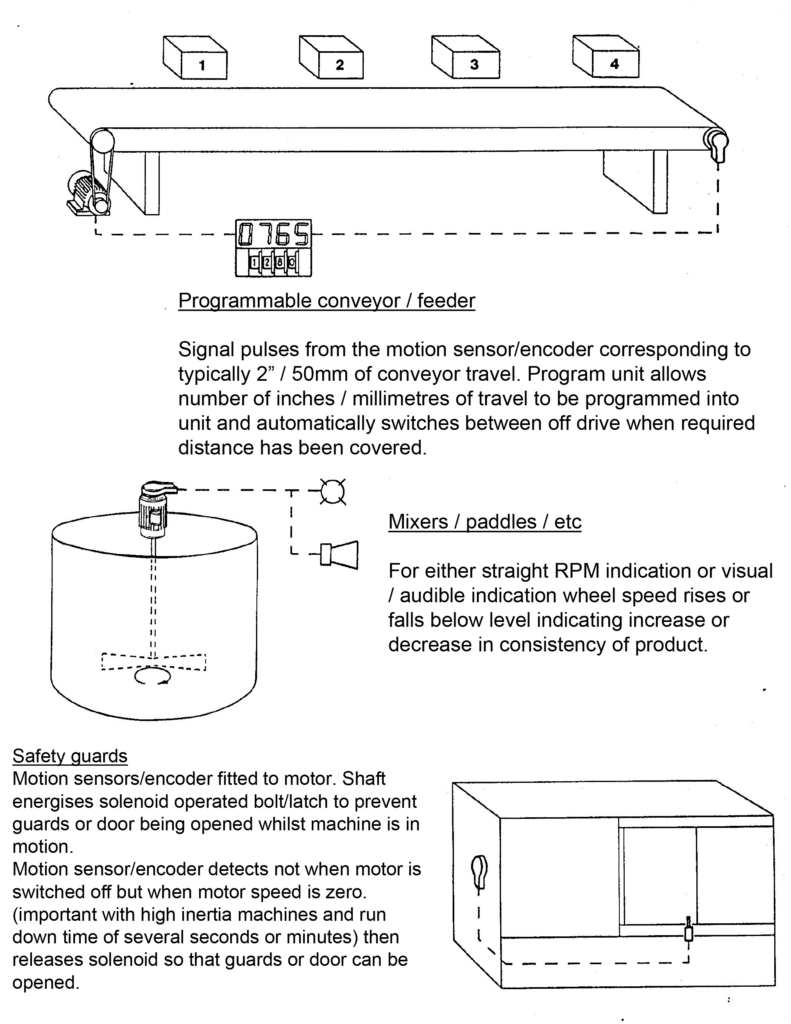

Other Applications

Speed Indication

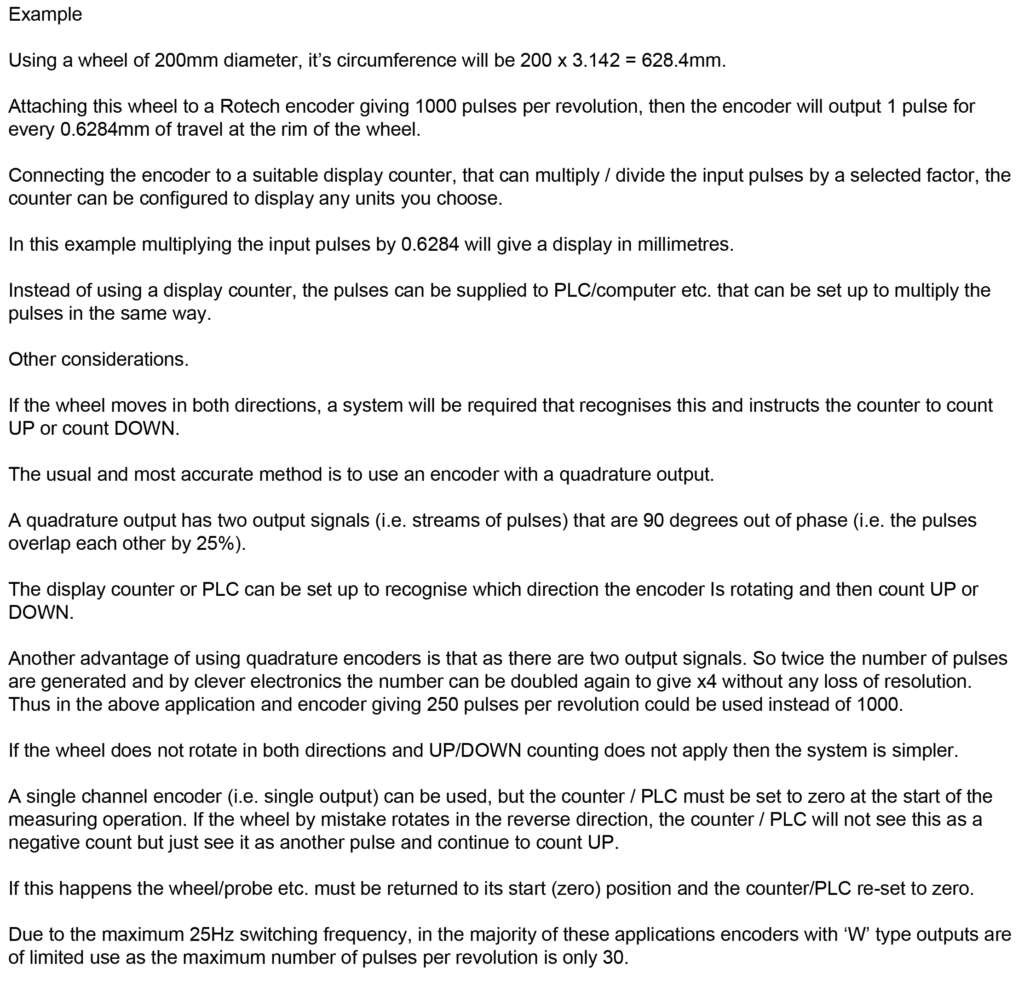

Length Measurement