Rotech Systems is now offering proven solutions for belt cleaning

This patented finger system offers a simpler, more cost-effective, and more reliable alternative to traditional motorised brushes and air knives. It’s designed to perform where other systems fail, with customisable options to fit even the most challenging mounting positions.

Belt Scrapers – Stainless Steel Tipped

We offer two high-performance chevron belt scrapers, designed to meet the specific demands of your industry, conveyor system, and material handling requirements.

Chevron & Flat Belt Scraper

Our flagship product, the Chevron Scraper, has been refined and proven over nearly two decades of field use. It features our trusted finger system and is available in two configurations:

- For flat belt applications

- For chevron or cleated belt applications

A wide range of blade types is available for both versions, ensuring optimal cleaning performance across various materials and operating conditions.

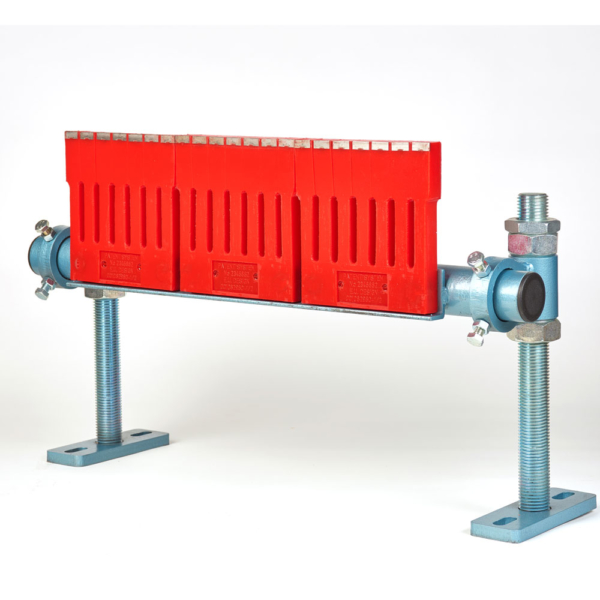

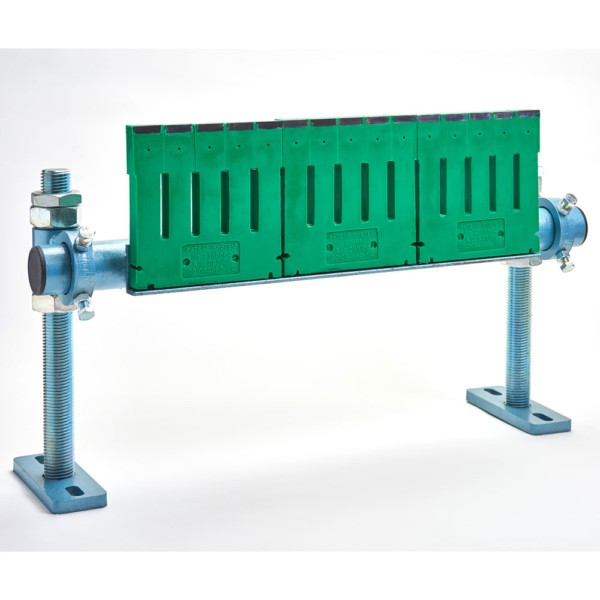

Duplex Scraper

The Duplex is our latest innovation, engineered specifically for cleated and profiled belts. While it incorporates our signature finger system, its distinctive staggered design enables it to clean belt types that traditional scrapers cannot. This unique solution offers unmatched efficiency and versatility in applications where other products fall short.

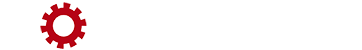

Belt Scrapers – Carbide Tipped

Our carbide-tipped belt scrapers are built to deliver outstanding performance across a wide range of conveyor systems and material handling applications. Designed to handle the most demanding environments, these scrapers are ideal for both flat and chevron belt configurations.

Chevron & Flat Belt Scraper

This advanced scraper is based on our long-standing finger system. It’s available in two tailored versions:

- For flat belt conveyors

- For chevron or cleated belts

Each version can be fitted with a variety of carbide-tipped blades, selected to match your specific application and material type. The result is superior cleaning efficiency, reduced maintenance, and longer service life—even under harsh operating conditions.

Tangential SLT

The Tangential SLT is our primary solution for flat-belt cleaning applications. It builds on our proven finger system, delivering reliable performance and minimal maintenance in a wide range of operating conditions.

What sets the Tangential SLT apart is its self-tensioning, spring-mounted design, which maintains consistent pressure against the belt for effective cleaning—without the need for frequent manual adjustments.

Thanks to the flexibility of the finger design, this scraper is also well-suited for use on convex or worn belts, where traditional rigid scrapers often struggle to maintain contact and performance.

Tandem Attachment

The Tandem attachment is designed to retrofit onto existing primary scraper units, offering enhanced cleaning performance without the need for a separate installation.

Available for both flat and chevron belts, this add-on unit improves material removal by tackling residual debris left behind by the primary scraper. It’s a simple, cost-effective way to boost efficiency, reduce material build-up, and extend belt life—with minimal downtime or modifications.

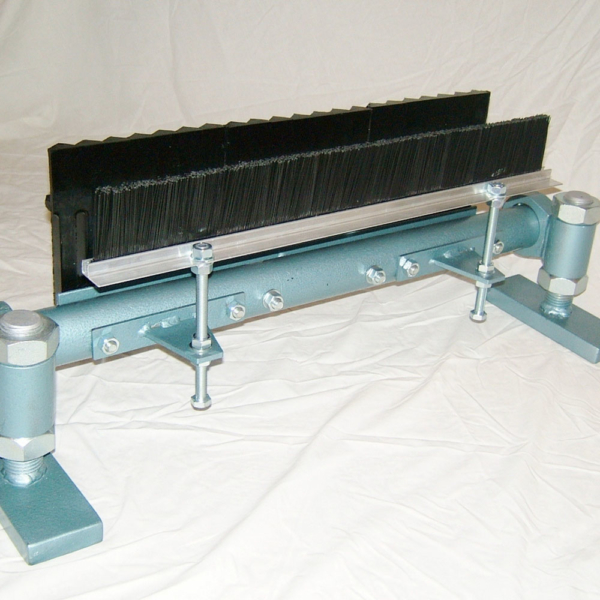

Secondary Brush Cleaner

This Secondary Brush Cleaner is designed to fit directly onto an existing primary unit, offering a simple and economical way to improve cleaning efficiency.

This is ideal for removing small amounts of dry or fine material that may pass under the primary scraper.

Recommended for lighter-duty applications, this compact unit helps reduce carry back, minimise maintenance, and improve overall conveyor performance—without the need for a full secondary system.